FRUITS & VEGETABLES

POST HARVESTING

PROCESSING

LINE

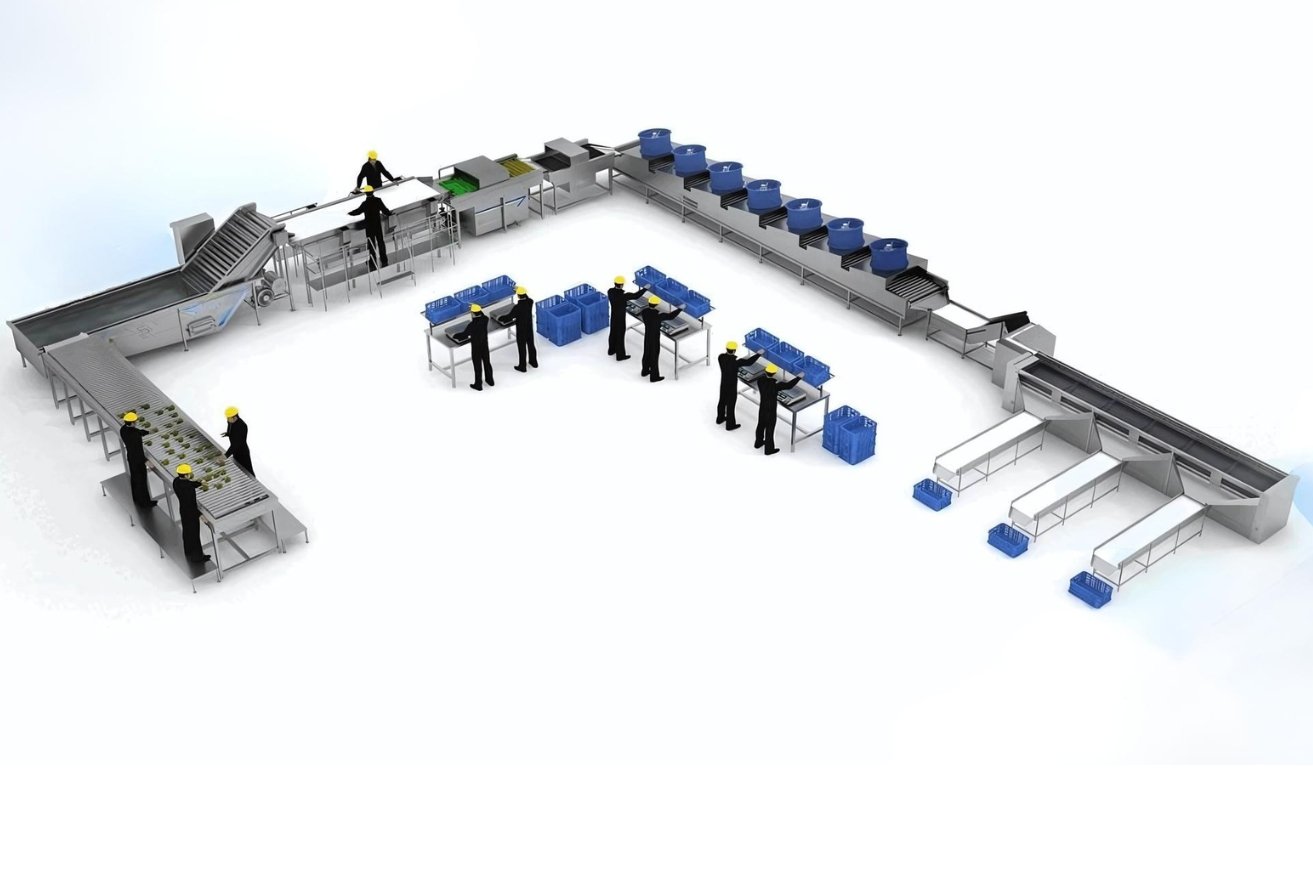

Fruits & Vegetables Packhouse Line

Naytrix Foodtek provides complete trunkey projects including manufacturing and supplying of fruits and vegetables processing/cleaning line.This fully automatic fruits and vegetables packhouse/cleaning line is designed for medium and large-scale post-harvest handling operations. With an optimized workforce of around 15 people, the complete line manages everything from raw produce unloading and washing to cleaning, drying, sorting, inspection, and packing.

We recognize that each packhouse has unique requirements. With output capacities ranging from 500 kg/hr to 5000 kg/hr, our fruit and vegetable processing lines are built to support both growing operations and established packhouses. For capacities above 5000 kg/hr, we also offer fully customized solutions tailored to your specific workflow and produce types.

Processing Plant

PROCESS FOR Fruits & Vegetables

01

Lifting Conveyor

The Elevator Conveyor is designed to gently lift and transfer bulk fruits and vegetables from the unloading or washing section to the Sorting &Inspection Conveyor. Built with food-grade materials and an inclined design, it ensures a smooth, controlled flow of product while minimizing damage during elevation. This step streamlines the handling process and ensures consistent feeding onto the inspection conveyor for effective quality sorting.

02

Sorting & Inspection Conveyor

The Sorting & Inspection Conveyor is a key component in the fruits and vegetables packhouse, enabling manual inspection and sorting of produce for quality control. Designed with a food-grade belt, adjustable speed, and ergonomic working height, it allows operators to efficiently remove damaged, under-ripe, or foreign materials. This ensures only high-quality produce moves forward for grading, packing, or further processing, helping maintain packhouse standards and customer satisfaction.

03

Bubble Washer with Ozone

The Bubble Washer with Ozone is designed to thoroughly clean fruits and vegetables using a combination of air agitation and ozone-infused water. The gentle bubbling action loosens soil, debris, and surface residues, while ozone provides effective sanitization by reducing microbial load without leaving chemical residues. This system ensures safe, hygienic produce while maintaining the natural texture and quality of the products. Ideal for delicate or high-value produce requiring a high standard of cleanliness.

04

Brush Cleaning (Optional)

The Brush Cleaning unit is an optional module designed to provide gentle yet effective surface cleaning for fruits and vegetables. Equipped with rotating food-grade brushes and water spray nozzles, it helps remove stubborn dirt, soil, and surface residues without damaging the produce. Ideal for root vegetables or firm-skinned fruits, this unit enhances overall cleanliness and improves the visual quality of the product before inspection or packing.

05

Air-Dryer

The Air Dryer is designed to remove excess surface moisture from washed fruits and vegetables using high-velocity, ambient or slightly warmed air. Strategically positioned air knives or blower nozzles ensure uniform drying without damaging delicate produce. This step helps prevent microbial growth, reduces product clumping, and prepares the produce for inspection, grading, or packaging. The Air Dryer enhances product shelf life and presentation while maintaining packhouse hygiene standards.

06

Inspection Conveyor

The Grading Machine is designed to sort fruits and vegetables based on size, weight, or shape, ensuring uniformity and meeting market or customer specifications. Equipped with precision rollers, belts, or sensors (depending on the model), it delivers accurate and consistent grading while maintaining high throughput. This automated process enhances efficiency, reduces labor, and improves overall product presentation and value in the supply chain.

07

Box Packaging

The Carton Box Packaging section is the final step in the Fruits &Vegetables packhouse line, where graded and sorted products are carefully packed into cartons for safe transport and storage. Designed for efficiency and minimal fruit handling, this stage ensures that Fruits & Vegetables reach the market in excellent condition, preserving both quality and appearance.

08

Move To Cold Storage

After completing all processing and packaging steps, the Fruits &Vegetables are transferred to cold storage to maintain their freshness, extend shelf life, and reduce spoilage. This temperature-controlled environment ensures that the quality of the fruit is preserved until it is ready for dispatch or distribution.

Comprehensive and Robust

Presence in Key Markets Across the Globe

We Have

Presence

Across India

24X7 After Sales Support

On Time Delivery Commitment

All India Strong Network

Competitive Price Range

Naytrix Foodtek Pvt. Ltd is a leading manufacturer and supplier of premium food processing equipment. We specialize in delivering turnkey solutions for Frozen Food Processing, Dehydration Processing Lines and Fruits and Vegetables Packhouses.