FROZEN

FRENCH FRIES

PROCESSING

LINE

Frozen French Fries Processing Line

Naytrix Foodtek provides complete turnkey projects including manufacturing of fully automatic frozen french fries processing line/plant is designed for medium and large-scale frozen french fries production. 18 people are enough to operate the complete french fries line from potato washing & to peeling. french fries cutting & blanching to french fries frying freezing & packing High automatic. continuous production, simple operation.

We believe that every business is unique. With output capacities ranging from 300kg/hr to 1000 kg/hr, our french fries plants are sure to suit the needs of most french fries manufacturers, whether you’re just beginning or are already an established manufacturer. For a capacity of over 1000kg/h, we can also customize it for you.

Processing Plant

PROCESS FOR French Fries

01

Lifting Conveyor

The lifting conveyor for the Drum Washer in the frozen French fries processing line is engineered to efficiently and continuously transport raw potato tubers to the Drum Washer unit. Constructed with food-grade materials and equipped with adjustable speed control, it ensures a smooth and consistent feed, optimizing the washing process. The gentle handling mechanism preserves the integrity of the potatoes, while the inclined design enhances workflow efficiency and reduces the need for manual labor in the initial stage of French fries production.

02

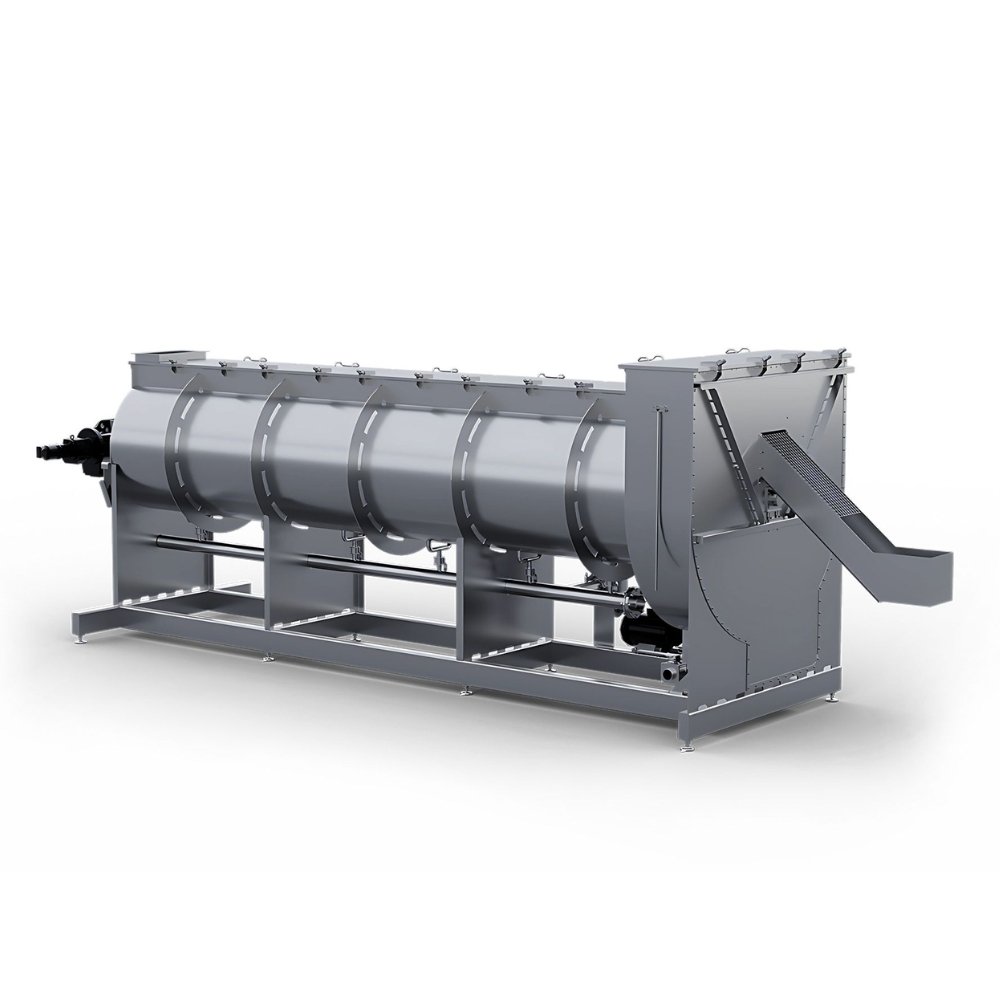

Drum Washer Machine

The drum washer is an initial and essential component in a frozen French fries processing line, designed to thoroughly clean raw potatoes before further processing. Using a rotating drum and a combination of water spray and gentle abrasion, it effectively removes soil, stones, and surface impurities without damaging the potatoes. This ensures a high level of hygiene and prepares the raw material for efficient peeling and cutting in the next stages.

03

Peeler Machine

The continuous-type emery peeler is a vital machine in the frozen French fries processing line, designed to efficiently peel washed potatoes using emery-coated rollers. As the potatoes pass through the rotating drum, the abrasive surface gently removes the skin with minimal product loss. Its continuous operation ensures high throughput, consistent peeling quality, and seamless integration with upstream and downstream equipment for optimized processing flow.

04

Cutter Machine

The cutter machine is a key component in the frozen French fries processing line, engineered to precisely cut peeled potatoes into uniform sticks of 6mm or9mm thickness. Equipped with interchangeable cutting blades and a high-speed rotary mechanism, it ensures clean, consistent cuts for optimal frying and packaging quality. Designed for continuous operation, the cutter supports high-capacity production while maintaining product integrity and minimizing waste.

05

Auger Blancher Machine

The auger blancher is a critical component in the frozen French fries processing line, designed to partially cook potato strips while enhancing product quality. It uses a rotating screw (auger) mechanism to gently convey the product through hot water or steam in a controlled environment. This continuous blanching process deactivates enzymes, improves texture, enhances color retention, and effectively removes surface starch from the potato strips. Removing excess starch is essential to prevent clumping, improve fry color, and ensure a crisp texture in the final product.

06

Air-Dryer

The air dryer is an essential unit in the frozen French fries processing line, used to remove surface moisture from blanched potato strips before frying or freezing. Using high-velocity ambient or slightly heated air, the machine gently and uniformly dries the product without affecting its texture or structure. Effective moisture removal helps prevent oil splatter during frying, improves oil absorption control, and enhances the overall quality and shelf life of the final product.

07

Fryer Machine

The fryer machine is a core component in the frozen French fries processing line, designed to precisely cook potato strips in hot oil to achieve the desired color, texture, and flavor. Available with either electric heating or thermic fluid (boiler-based) heating systems, the fryer ensures consistent temperature control for uniform frying. Its continuous design, combined with adjustable frying time and oil flow, supports high-capacity production while maintaining product quality. The choice of heat source allows flexibility based on energy availability, operational cost, and plant setup.

08

IQF Tunnel

The IQF (Individual Quick Freezing) tunnel is a vital unit in the frozen French fries processing line, designed to rapidly freeze fries while maintaining their individual shape, texture, and quality. Using a continuous belt system and high-velocity cold air circulation, the tunnel ensures uniform freezing of each fry, preventing clumping and preserving product integrity. This quick freezing process locks in freshness, extends shelf life and prepares the product for efficient storage and distribution.

09

Label & Packaging

The packaging line is the final and essential stage in a frozen French fries processing line, tasked with precisely weighing, filling, sealing, and labeling the finished product. Engineered for high efficiency and strict hygiene standards, the packaging line ensures that frozen French fries are securely packed to maintain product integrity, prevent contamination, and comply with market requirements. Capable of handling various bag sizes and packaging formats, it caters to both retail and bulk distribution demands.

10

Storage

Final product storage is a critical stage in the Frozen French Fries processing line, where packaged products are kept in cold storage facilities to maintain their quality and extend shelf life. These storage areas are maintained at consistently low temperatures to preserve the texture, flavor, and nutritional value of the frozen vegetables until they are ready for distribution.

Comprehensive and Robust

Presence in Key Markets Across the Globe

We Have

Presence

Across India

24X7 After Sales Support

On Time Delivery Commitment

All India Strong Network

Competitive Price Range

Naytrix Foodtek Pvt. Ltd is a leading manufacturer and supplier of premium food processing equipment. We specialize in delivering turnkey solutions for Frozen Food Processing, Dehydration Processing Lines and Fruits and Vegetables Packhouses.