FROZEN

VEGETABLES

PROCESSING

LINE

Frozen Vegetables Processing Line

A sliced vegetable frozen processing line is designed to efficiently slice, freeze, and package vegetables for long term storage and distribution. The process begins with the washing and peeling of vegetables, followed by precise slicing to desired thickness. After slicing, the vegetables are quickly frozen using methods such as flash freezing or blast freezing to lock in freshness, texture, and nutritional value.

The frozen slices are then packaged in airtight containers or bags to prevent freezer burn and ensure quality. This processing line is ideal for producing frozen vegetable products that maintain their flavor and nutritional integrity for extended periods.

Applicable for all type of Fruits & Vegetables

PROCESS FOR FROZEN VEGETABLES

01

Slicer Machine

The slicer machine is a crucial component in a frozen vegetable processing line, designed to cut vegetables into uniform slices quickly and efficiently. It ensures consistent product size and quality, which is essential for even freezing and appealing presentation. With adjustable cutting settings and high-speed operation, the slicer enhances productivity while maintaining the integrity of delicate vegetables. Its stainless-steel construction and easy-to-clean design make it ideal for hygienic food processing environments.

02

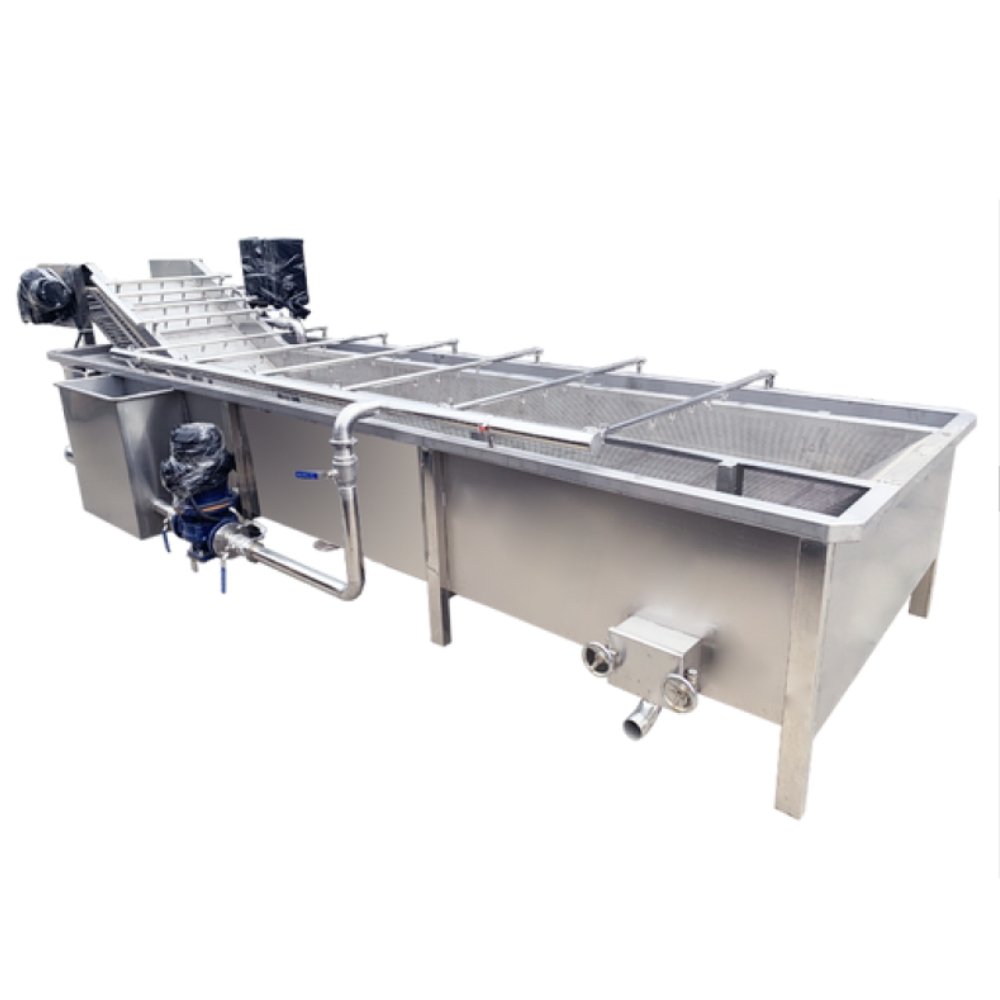

Bubble Washer Machine

The bubble washer machine is a key component in frozen vegetable processing lines, designed to ensure thorough and gentle cleaning of raw produce before further processing. Utilizing a combination of water and air bubbles, this machine effectively removes dirt, pesticides, and other impurities from vegetables without causing damage. Its efficient design not only enhances food safety and hygiene but also helps maintain the quality and freshness of the vegetables throughout the processing cycle.

03

Blancher Machine

The blancher machine is an essential unit in frozen vegetable processing lines, designed to partially cook vegetables through controlled heating before freezing. This process inactivates enzymes, preserves color, texture and nutritional value, and prepares the vegetables for optimal freezing and long-term storage. With precise temperature and timing control, the blancher ensures consistent product quality and enhances shelf life.

04

Cooling Tank

The cooling tank machine is a vital component in frozen vegetable processing lines, used immediately after blanching to rapidly reduce the temperature of vegetables. This quick cooling process, typically done with chilled water, helps halt the cooking process, preserve texture, and maintain color and nutritional quality. Efficient and consistent, the cooling tank ensures the vegetables are properly conditioned for the next stage—freezing.

05

De-Watering Shaker Machine

The dewatering shaker is an important machine in frozen vegetable processing lines, designed to remove excess surface water from vegetables after washing or cooling. Using gentle vibration and a perforated surface, it efficiently reduces moisture content without damaging the product. This step is crucial for improving freezing efficiency, preventing ice formation, and maintaining product quality during storage.

06

IQF (Individual Quick Freezing)

The IQF (Individual Quick Freezing) machine is a core component in frozen vegetable processing lines, designed to freeze vegetables rapidly while keeping them separate from one another. This quick freezing method preserves the natural texture, flavor, color, and nutritional value of each piece, ensuring high-quality frozen products. Ideal for a wide range of vegetables, the IQF machine enhances product shelf life and prevents clumping, making it essential for modern frozen food production.

07

Label & Packaging

The packaging line is the final and crucial stage in a frozen vegetable processing line, responsible for accurately weighing, filling, sealing, and labeling the finished products. Designed for efficiency and hygiene, the packaging line ensures that frozen vegetables are securely packed to preserve freshness, prevent contamination, and meet market standards. With options for various bag sizes and packaging formats, it supports both retail and bulk distribution needs.

08

Storage

Final product storage is a critical stage in the frozen vegetable processing line, where packaged products are kept in cold storage facilities to maintain their quality and extend shelf life. These storage areas are maintained at consistently low temperatures to preserve the texture, flavor, and nutritional value of the frozen vegetables until they are ready for distribution.

Comprehensive and Robust

Presence in Key Markets Across the Globe

We Have

Presence

Across India

24X7 After Sales Support

On Time Delivery Commitment

All India Strong Network

Competitive Price Range

Naytrix Foodtek Pvt. Ltd is a leading manufacturer and supplier of premium food processing equipment. We specialize in delivering turnkey solutions for Frozen Food Processing, Dehydration Processing Lines and Fruits and Vegetables Packhouses.